Yazaki and Toray Develop Recycled Resin for Car Parts, Aiming for Lower Emissions

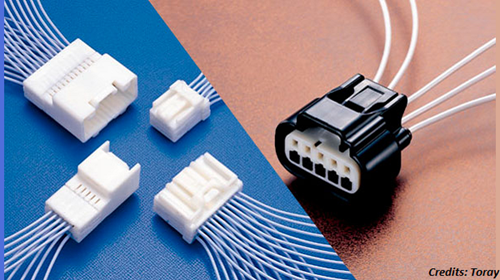

Yazaki Corporation and Toray Industries, Inc. announced a collaboration to create a new type of resin for automotive parts. This resin, a recycled form of polybutylene terephthalate (PBT), will be used in connectors for car wiring harnesses.

The new resin is made from scrap materials left over from manufacturing processes. Yazaki says this will result in lower carbon dioxide emissions compared to using virgin materials, without sacrificing performance.

Chemical Recycling Ensures Quality

The recycled resin, called Ecouse TORAYCON™, is produced by Toray through a process of chemical recycling. This method breaks down scrap materials and rebuilds them into a usable resin.

One challenge of using recycled materials is maintaining quality, especially for critical car parts. Yazaki addressed this by working with Toray to optimize the properties of the recycled resin for use in connectors. This ensures the new material performs just as well as virgin PBT resin.

Benefits and Next Steps

The new recycled resin offers two key benefits:

- Lower CO2 emissions during production compared to traditional PBT resins.

- Equivalent performance, moldability, and quality stability compared to traditional PBT resins.

Yazaki and Toray will showcase connectors made with the new resin at their booths at the upcoming Automotive Engineering Exposition 2024 YOKOHAMA, which takes place May 22nd through 24th.

This collaboration between Yazaki and Toray represents a step towards a more sustainable automotive industry, with a focus on reducing waste and emissions.